AMOROSO CASE STUDY

Amoroso’s Baking Co. Realizes Significant Reduction in Distribution Costs Using RLS Logistics’ AccelefrateSM Consolidation Program

The key component of a Philly cheesesteak sandwich is the roll. Nobody knows this better than the Amoroso’s Baking Co. of Philadelphia. Known as the company that “makes the rolls that make Philly sandwiches world famous,” Amoroso’s Baking Co. distributes its products nationwide so that everyone everywhere can enjoy the authentic taste of Philly. In business for over a century, the family-owned and operated company supplies Italian bread and rolls locally through its fresh distribution business, and nationwide through its Frozen Foods Division.

Multi-Vendor Consolidation Helps Maintain Competitive Advantage

Distributing products in over 40 states can be a challenge according to Bob Rector, Director of Amoroso’s Baking Co.’s Frozen Foods Division. “We are an east coast company,” he explained. “In order to compete in states where there are local bakeries, we have to keep our delivered prices lower. The new AccelefrateSM multi-vendor freight consolidation program from RLS Logistics gives us that competitive advantage. It allows us to costeffectively distribute product to any of our customers anywhere in the United States.”

Logistics Solution Enables Economies of Scale

AccelefrateSM is a combined warehouse and transportation service designed to deliver products at a lower cost by combining orders with those of other Accelefratesm shippers to create full truckload shipments for scheduled delivery. Describing the program, Russell Leo, President/CEO of Transportation for RLS, said “It’s a logistics strategy that enables considerable economies of scale, thereby greatly reducing the transportation cost per unit weight.” The significantly reduced transportation rates are guaranteed when a customer maintains an inventory at one of the RLS Logistics’ three temperature-controlled warehouse facilities — Newfield, NJ, Vineland, NJ and Pittston, PA. The savings can be quite substantial. “Approximately 30-40% off traditional LTL costs,” according to Preston Thomas, Chief Financial Officer at Amoroso.

Guaranteed Rates — A Significant Advantage

Prior to signing on to the AccelefrateSM program, Amoroso’s Baking Co. divided its distribution operation among a number of companies, including RLS Logistics. “We’ve enjoyed a great relationship with RLS for over twenty years,” said Rector. “When they introduced their AccelefrateSM program, the guaranteed rates were so advantageous that we decided to use them exclusively.”

Better Inventory Management

Amoroso’s Baking Co. stores all its frozen bread and rolls at RLS’ Newfield, NJ warehouse location. “We use the program’s shuttle service,” said Rector. “RLS drops trailers at our production facility; when we fill the trailer they send over a driver; he pulls the trailer and brings it to the warehouse for us.” RLS has dedicated a portion of the warehouse to storing products used to fill Amoroso’s Baking Co.’s orders. “We are two companies growing together,” said Rector. “As we’ve grown, RLS has been able to make accommodations for us so they can better manage our inventory.”

Worry-Free Process

One of the major advantages of the AccelefrateSM program is the convenience of dealing with a single logistics provider. Once an order is received at the warehouse, RLS handles the rest internally until the shipment is delivered. “It’s a worry-free process,” explained Rector. “RLS understands our business — they know the value we put on on-time delivery and a timely response to any customer issue. If there is an issue, it’s just one phone call and RLS handles it.”

Trust in Emergencies

The trusting relationship between RLS and Amoroso’s Baking Co. is especially evident when it comes to handling emergencies. “If we have an emergency, RLS will do everything necessary to accommodate us,” said Rector. “We have a person assigned to us who is very knowledgeable. Her name is Gloria. If she can’t contact us, she makes really educated decisions because she knows us well enough to know what we would do.”

Eliminates the Need for a Logistics Staff

Because of the AccelefrateSM program and people like Gloria, Amoroso’s Baking Co. has no need for a logistics person on its payroll. “Logistics is an important part of getting the product to the end user; it is a major component of business strategy,” emphasized Thomas. “Freight is very costly and RLS’ logistics solutions help us stay competitive.”

Guaranteed Sailing Schedule

While some consolidation programs offer inconsistent delivery schedules, RLS AccelefrateSM has a defined delivery schedule that is consistent week to week. RLS delivers to every point in the U.S. at a minimum of once per week with some regional areas getting serviced twice a week. “When we receive an order from one of our distributors, we can tell them it’s going to be shipped on a specific day,” said Thomas. “We know with confidence when it’s going to leave the RLS warehouse and when they will take delivery.”

Access to information Throughout Transportation Cycle

“RLS provides critical information on our shipments throughout the transportation cycle,” said Rector. “If a truck breaks down we receive continuous updates on what the problem is and when it will be fixed. If it’s a freezer issue, RLS will get another truck under the trailer before there is an issue with the product. When the situation is resolved, RLS sends us a follow-up e-mail to that effect.”

Service and Integrity

“Consistency, dependability and follow-up,” is how Thomas describes RLS’ service. “While there are a number of companies that provide freezer service as well as transportation, it would be difficult for any of them to provide the level of service we receive from RLS,” he said. “RLS is a company that has integrity, which is important in this industry because there are some operators who don’t operate honestly. We are a good fit for one another.”

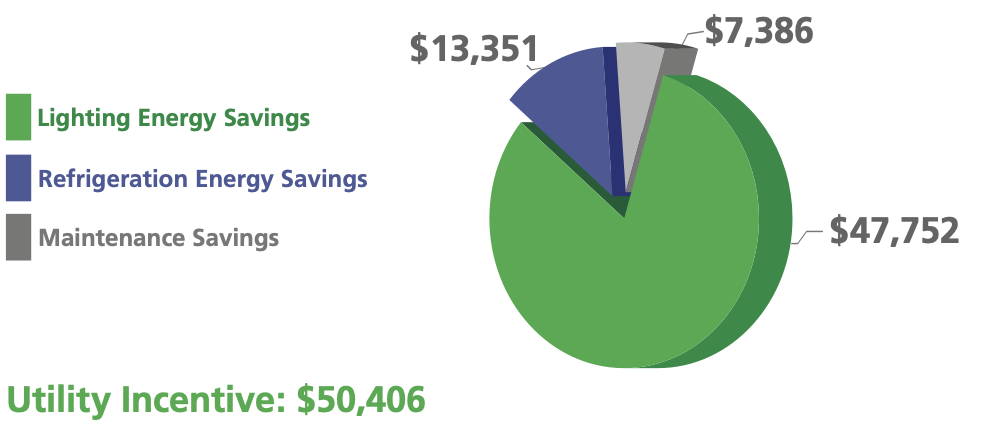

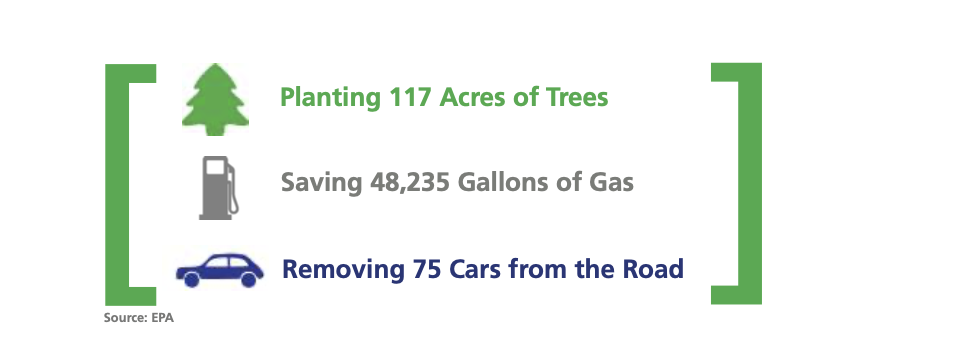

Green Impact

This project has led to the equivalent reduction of 795,872 pounds of carbon dioxide, removing pollutants from the air and having the same effect on the environment as:

Amoroso’s Baking Co.

A History of Quality and Reliability

For over 100 years, the Amoroso’s Baking Co. name has stood for the highest quality hearth baked bread and rolls. Beginning in Camden, NJ in 1904, Vincenzo Amoroso and his two sons, Salvatore and Joseph, started baking Italian bread from a carefully guarded recipe that Vincenzo had brought with him from the old country. The family’s strict adherence to unwavering quality soon created such a demand that they expanded their bread making operations to Philadelphia.

By the early 1930’s, Salvatore had taken over the family business, and with the help of his four sons, Daniel, Vincent, Leonard, and Salvatore Jr., the business continued to grow. World War II saw the end of home deliveries and the beginning of the supermarket era. The popularity of the Amoroso’s Baking Co. brand on local supermarket shelves led the Company to expand its distribution to neighboring counties and states.

In the 1970’s, Amoroso’s Baking Co. established its Frozen Foods Division. Through its national distribution supply chain, the Company’s frozen “Thaw and Serve” and “Par-Baked” programs are able to deliver bread and rolls anywhere in the United States and internationally.

Today, after five major expansions, the Amoroso’s Baking Co.employs more than 300 people. Although many things have changed during the past century, two things have remained the same: the Amoroso’s Baking Co. family still owns and manages the bakery; and their insistence on unwavering quality — the quality that “makes the rolls that make Philly sandwiches world famous.”