SMART WATT CASE STUDY

Commercial, Industrial & Institutional Division

Refrigerated & Freezer Warehouse Case Study

The Company

RLS Logistics, headquartered in Newfield, NJ, is a leading temperature-controlled logistics provider. The company’s one-stop integrated supply chain solutions include transportation, warehousing, packaging and distribution services to customers in the frozen and refrigerated food industry.

RLS Logistics is dedicated to environmental conservation and has taken many steps to integrate sustainable practices into all aspects of operations. The company has recently been recognized by Food Logistics magazine as a “Top Green Provider” of 2012 and 2013 for initiatives implemented, including the use of solar electricity and the installation of energy-efficient lighting technologies.

The Challenge

RLS Logistics contacted SmartWatt Energy to perform a full-building audit of all lighting systems throughout their Pittston, PA facility, including office space and a freezer warehouse, for potential energy-savings upgrades. The company’s goals were to reduce their environmental impact and to dramatically improve the quality and quantity of light for employees.

Smart Savings

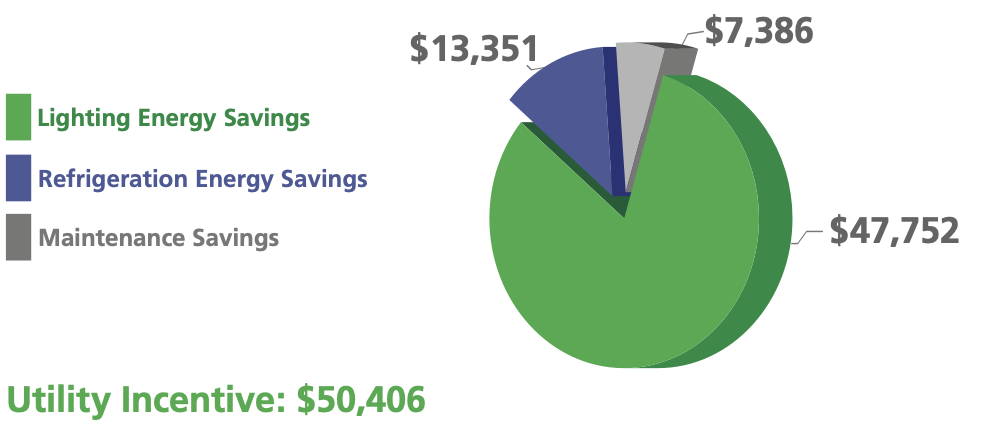

In addition to improved working conditions, RLS Logistics will enjoy the following realized energy savings from this fluorescent and LED lighting upgrade project:

Green Impact

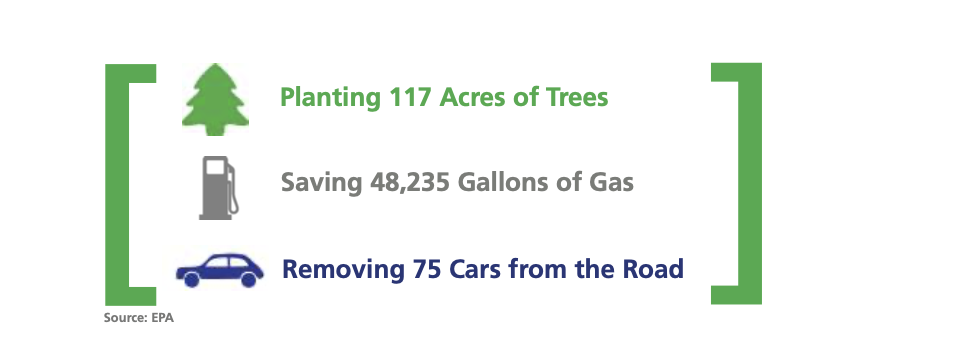

This project has led to the equivalent reduction of 795,872 pounds of carbon dioxide, removing pollutants from the air and having the same effect on the environment as:

RLS Logistics

Temperature-Controlled Logistics Provider

Replacement of T-12 fluorescent and metal halide lighting fixtures with T-8 fluorescents throughout office space and LEDs throughout freezer warehouse and loading dock areas, helped RLS Logistics shed 127.24 kW from their facility, with a payback period of approximately 12 months.

Above: RLS Logistics’ Pittston, PA Facility